RFID Operation, Applications, and its Limitations in Agriculture/Food Sector

Mate Liszi, Attila Kovacs

Description

Keywords: precision agriculture; animal identification; food traceability; field-to-fork; semi-active tag; smart packaging; RFID

H2020 challenge: Food Security, Sustainable Agriculture and Forestry, Marine, Maritime and Inland Water Research and the Bioeconomy

Knowledge and skills (P: prerequisite; D: desirable, but not necessary): Electronics (P), RFID (P), Cloud technology (P), Manufacturing technologies of RFID (D), Data pre-procession in cloud technology (D), Sensor management (D), Understand the field-to-fork concept (D)

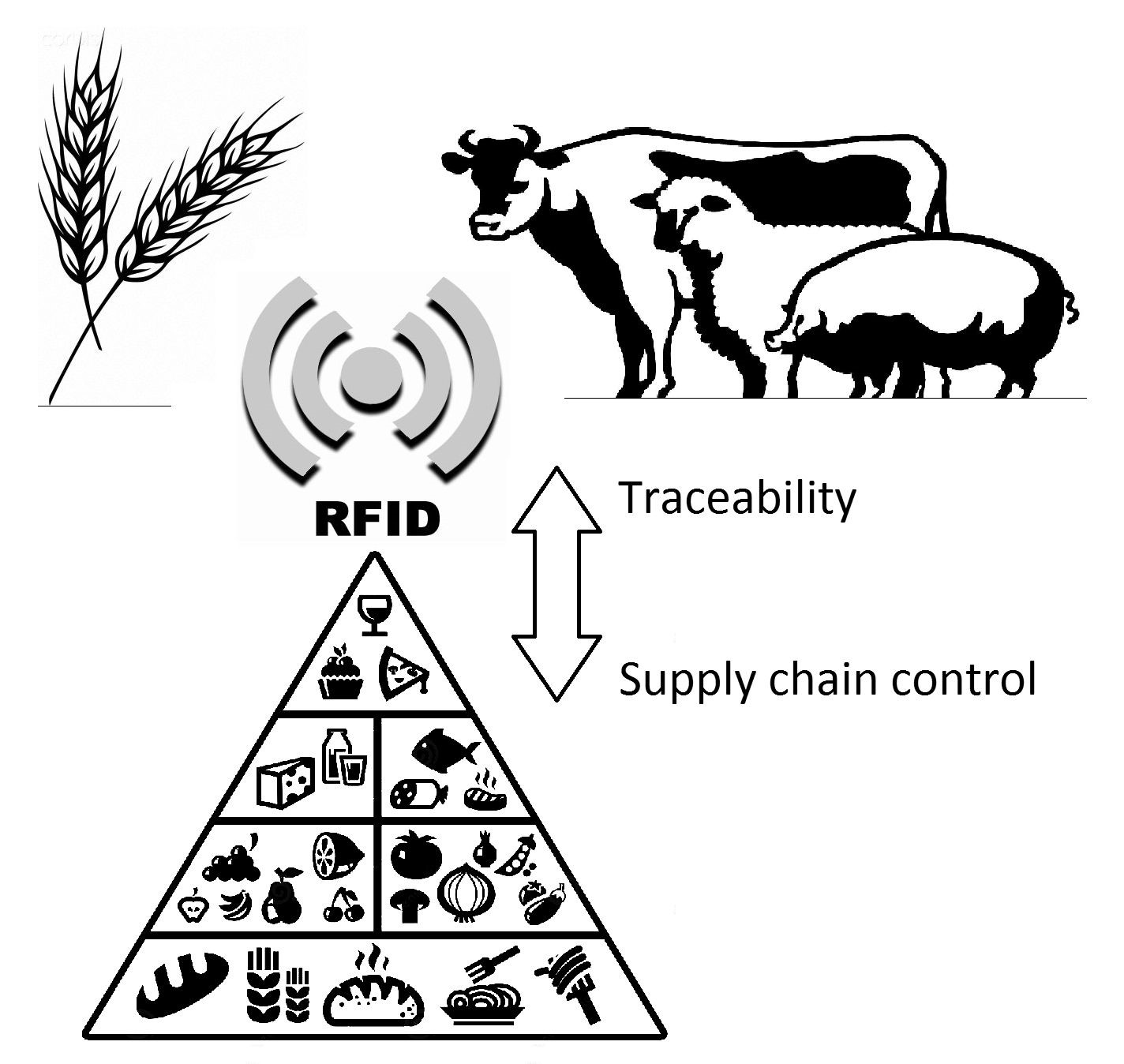

There is a general need for our society to have healthy food supply. In the EU, the food safety is also a growing concern. One way to ensure wholesome food (and animal feed) product is to establish good traceability from field-to-fork. Organizations such as the European Safety Authority (EFSA), which is responsible for food safety, are establishing procedures to collect and analyse data in field of food (feed) in order to identify emerging risks. On the other hand, recent advances in RFID (Radio-Frequency IDentification) technology offer vast opportunities for research, development and innovation in agriculture. RFID has been used for years in animal identification and tracking, being a common practice in many farms. Additionally, it has been used in the food chain for traceability control. Implementation of sensors in tags enables the development of new applications in fields, including environmental monitoring, irrigation, specialty crops and farm machinery. However, there are also challenges and limitations that should be faced in the next years, such as [1]: (i) operation in harsh environments (e.g., with dirt and/or extreme temperatures); (ii) huge volumes of data that are difficult to manage; (iii) need of longer reading ranges, due to the reduction of signal strength caused by propagation in crop canopy; (iv) understanding behaviour of the different frequencies and identifying which is the right one for each application; and (v) diversity of standards and the level of granularity.

The aim of the case study is to gather information and to start developing an RFID application which offers cheap, cost effective solution for entrepreneurs who do either livestock breeding or crop farming, including food production and supply chains. The work has to be focused mainly to the above-mentioned farming levels. At the end of the case study solution, proposals need also to address a sustainable, standardisable „field-to-fork“ concept to optimize supply chain with RFID technologies, giving opportunity to overthrow unnecessary long trade routes which are typical of nowadays EU’s product flow.

INNOSOC students, supervised by INNOSOC lecturers, will collaborate on providing a possible solution to this Case Study. These activities will be conducted as a part of the ERASMUS+ blended mobility and will be finalized during the INNOSOC Valencia 2017 workshop in late May 2017.

As the world population grows, we, Europeans, have to face bigger problems than producing food, so the time is now to create a solution for automating all processes that can be automated by nowadays technology. The manufacturing industry is highly automated and therefore machines, chemicals, medicines, electronics are made in clean and closed facilities. We somehow forget easily that we eat products given to us by open and dirty fields. Therefore, we have to devote proper attention to what we eat, its safety, and its place of origin, similar as we choose better machines and safer cars. Food security, covering the whole food chain and related services from primary production to consumption, is one of the (if not the) most important aspect of human life because food consumption has an impact on human health and the environment. Advancements in technology will help us to fulfil requirements for assuring food security. The aim is to allow tagging of agricultural products or livestock for better traceability and subsequent big data processing, optimizing the whole agricultural process.

This case study provides insights in agriculture and food security for engineering students. There are very few engineers working at this field, as an ordinary engineer works, for example, on developing machines, manufacturing processes, plans buildings, factories, or electronic schematics. There will be efforts given to endear agriculture for students alienated from this fantastic world of animals and plants, living beings. Students will have to find compatibilities between agronomics and engineering, with the help of an agricultural engineer, from a country with great agricultural history.

One of the aims of INNOSOC is to set up a transnational multidisciplinary intensive study program in the field of innovations based on ICT targeting societal challenges defined by Europe 2020 and Horizon 2020 programs. In our case combining RF technologies into food chain fulfils the criterion of INNOSOC philosophy. Radio frequency identification (RFID) tags, in combination with ICT, are expected to improve logistics and value chain management. RFID technology can help detect the quality and origin of goods prior to entering a supermarket for sale, or a processing factory, much more efficiently and consequently significantly increase transparency of the flow of goods. This technology has a likelihood of being fully implemented and having a relatively large impact on the food chain by 2025.

[1] Ruiz-Garcia, L. and Lunadei, L. (2011). The role of RFID in agriculture: Applications, limitations and challenges. Computers and Electronics in Agriculture, 79(1)

[2] Jacob, M., Farrell, P. and Brodie, G. (2015). Microwave and Radio-Frequency Technologies in Agriculture. An Introduction for Agriculturalists and Engineers. 1st ed. Warsaw/Berlin: De Gruyter, pp.345-348, pp.1-17, p.25.

[3] R. Hornbaker, V. Kindratenko, and D. Pointer (2004). An RFID Agricultural Product and Food Security Tracking System Using GPS and Wireless Technologies.

[4] Bowman, K.D., (2010). Longevity of radiofrequency identification device microchips in citrus trees. Hortscience 45 (3), 451–452. [5] Yang, I.-C., Chen, S., Huang, Y.-I., Hsieh, K.-W., Chen, C.-T., Lu, H.-C., Chang, C.-L., Lin, H.-M., Chen, Y.-L., Chen, C.-C., Lo, Y.M., (2008). RFID-integrated multi-functional remote sensing system for seedling production management. In: 2008 ASABE Annual International Meeting. Providence, Rhode Island, USA. [6] Luvisi, A., Panattoni, A., Bandinelli, R., Rinaldelli, E., Pagano, M., Gini, B. and Triolo, E. (2010). RFID microchip internal implants: Effects on grapevine histology. Scientia Horticulturae, 124(3), pp.349-353. [7] Luvisi, A., Triolo, E., Rinaldelli, E., Bandinelli, R., Pagano, M. and Gini, B. (2010). Radiofrequency applications in grapevine: From vineyard to web. Computers and Electronics in Agriculture, 70(1), pp.256-259. [8] Ruiz-Garcia, L., Steinberger, G. and Rothmund, M. (2010). A model and prototype implementation for tracking and tracing agricultural batch products along the food chain. Food Control, 21(2), pp.112-121. [9] T. M. Brown-Brandt, T. Yanagi, Jr., H. Xin, R. S. Gates, R. A. Bucklin, and G. S. Ross, (2003). A new telemetry system for measuring core body temperature in livestock and poultry. Applied Engineering in Agriculture, 19(5). [10] Voulodimos, A., Patrikakis, C., Sideridis, A., Ntafis, V. and Xylouri, E. (2010). A complete farm management system based on animal identification using RFID technology. Computers and Electronics in Agriculture, 70(2), pp.380-388.Questions that need answers

- What are the EU regulations and incentives related to food (feed) traceability?

- What are the key players in the food (feed) chain (from field-to-fork)?

- What are the most common hazards that aimed to be avoid by RFID techniques?

- What are the challenges implementing RFID in food chains?

- What are the advantages of RFID over barcode?

- What are the advantages of RFID over identification brands, tattoos, eartags?

- What are technical parameters of using RFID technologies?

- What is the average stored data in RFID chips?

- How to implement and use tags on animals and plants?

- What procedures needed to be taken to gather information from the tag?

- What is cold chain?

- How to handle the vast number of data?

- What is FEFO? How to implement it in a small shop?

- How could this solutions break the status quo of bad habits of European agriculture and consumer society, as wasting, unnecessary torture to animals, and long polluting truck trade routes?

Case study supervisors

Mate Liszi

Lecturer

Attila Kovacs

Lecturer

Case study students

Hrvoje Vdović

INNOSOC 2017 Student

Jan Rabcan

INNOSOC 2017 Student

Enrique López Oliver

INNOSOC 2017 Student

Grégoire Saillour

INNOSOC 2017 Student